INFORMATION

Air flow in multi oven

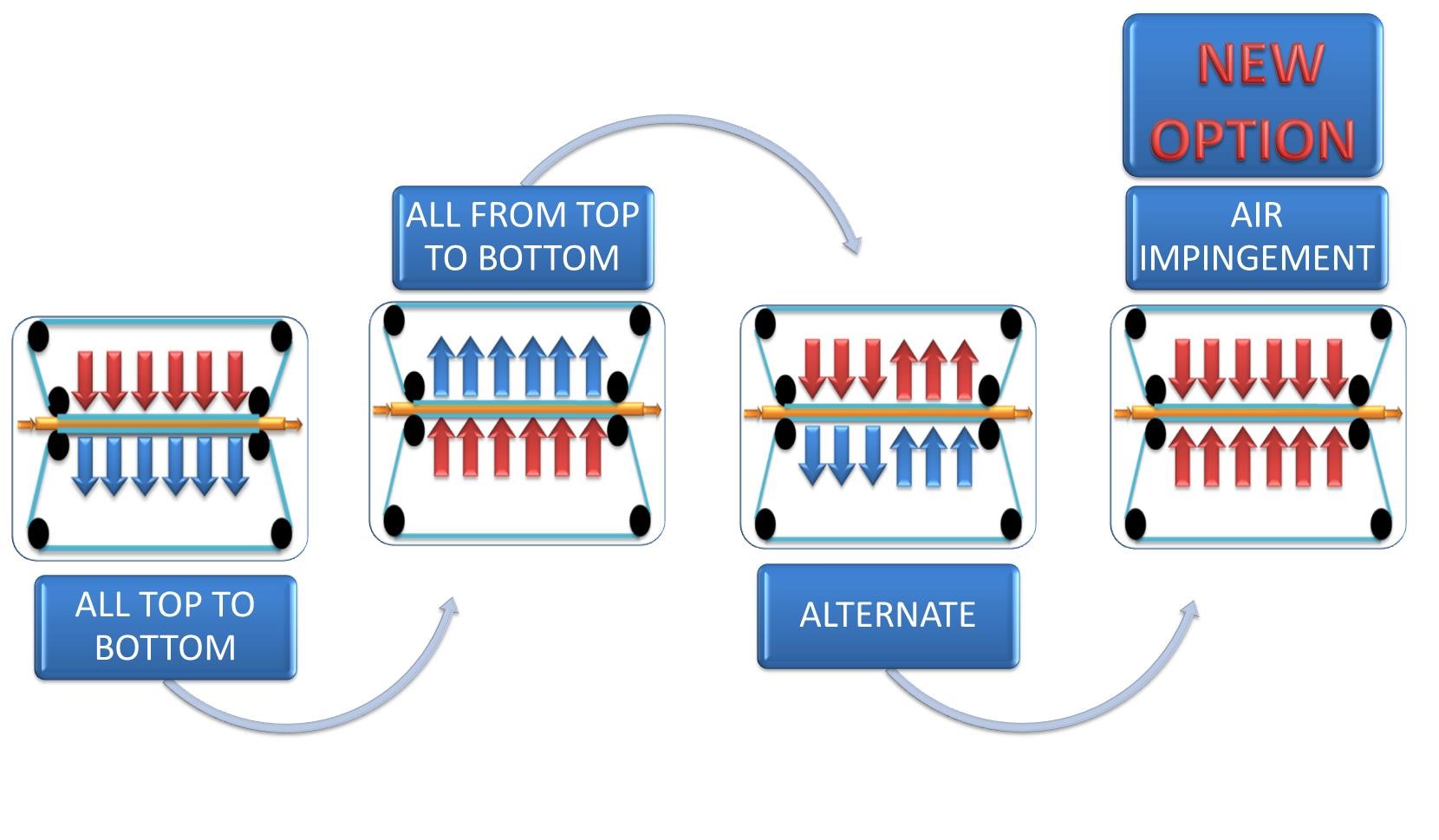

Optionally the multi oven could be equipped with the possibility of air impingement flow in one or in all sections. This is used for special applications or air permeable products.

Remain however the possibility of working with air trough system = customer could choose the way to work, without changing the oven.

Line will be extremely versatile and always future proof.

Description of air trough working is the same of other ovens.

Web thickness regulation

Webs coming from a carding + cross lapper system or from an air lay must be protected and controlled in thickness,

in order to meet final user demand. For this reason a fiber bat is held between two conveyors, before to enter into

the oven and all along the process . In this way the top belt will prevent fiber movement and will adjust final thickness.

Belts distance is regulated gradually in various points, with motor driven screw jacks. They are controlled from the

touch panel so the operator can adjust easily in any moment following the final product. The compression is gentle

and gradual, thanks to various points of regulation located along the oven length.

Motor driven screw jacks

Motors for belts distance adjusting are located out of the oven in clean and cold atmosphere.

Belts

Following the products our oven could install different belts and different combinations. our great experience guide us in the choose of various materials and mashes fiberglass ptfe coated, steel, pps, peek, duofill , hybrid are among the more common used type.

Air filter

Easy to clean filters

For no stop production

Air stream may remove fibers and dust from the web and they will reach burner zone with risk of contamination, burner damage, fire.

To prevent this, air flow is continually filtered before reach the burner at each cycle. Each burner has 3 set of filters that could be cleaned from outside of the oven, without doors opening.

Doors

Oven is equipped with various doors that are used to access to the internal parts, for cleaning and maintenance. The sealing of the smoke is made with silicon gasket. To get the optimum sealing the doors are equipped with 4 locks (2 on the left, 2 on the right). These, jointed with special hinges permit a parallel movement of the door that will close perfectly with oven frame.

Teleservice

Production site, located in any place of the world, is connected via internet with our systems in Italy. Customer is assisted in real time for any kind of problems, modifications, future adding without the need to send locally a technician.

Multi oven is studied to meet any kind of customer needs, with various fibres blends, web thickness and weight. Optionally it could be equipped with impingement air flow (see after) in one or all sections. It is equipped with double belts with adjustable distance (see after)

ENTRY ZONE : it will contains various belts mechanisms, that will remain in cold atmosphere

SECTION 1 : equipped with fan, burner, filters

SECTION 2 : equipped with fan, burner, filters

SECTION 3 : equipped with fan, burner, filters

SECTION 3 : number of sections following the production

AIR EXHAUST FAN : to remove smokes from oven

EXIT ZONE : it will contains various belts mechanisms, that will remain in cold atmosphere

FAN OF THE SECTION : at variable speed

BURNER OF THE SECTION : industrial type, world wide assisted and equipped with filters

| FIBERS | PES, PE, PA, WOOL, COTTON, RECYCLED FIBERS, KENAF, HEMP, FLAX, FEATHERS, FOAM CHIPS, NEWSPRINT, DUST FROM FILTERS, FIBER IN RUBBER TIRE, BiCo |

| WORKING WIDTH | 1.500-6.000mm |

| WEIGHT RANGE | 50-15.000gsm |

| WEB THICNESS BEFORE THE OVEN | Up to 1.500mm |

| WEB THICNESS AFTER THE OVEN | Up to 300mm |

| PRODUCTION SPEED | Up to 100m/min |

| HEATING | Direct gas burners (with natural or lpg gas), thermal oil, electric |

| OVEN SECTION LENGHT | 3.300mm or 2.200mm |

Equipped with steel belts, multi functions ovens find application in variety of applications: Natural fiber, Foam chops, Filters dust, Rubber tire, wood sawdust, newsprints, etc. etc. could be mixed in variable proportion with bonding fiber to form a web to be fixed into the oven, equipped with double belts.

The belts also prevent shrinkage of the web during bonding and setting, consequently the stability of the web is increased.